From the idea to the finished product.

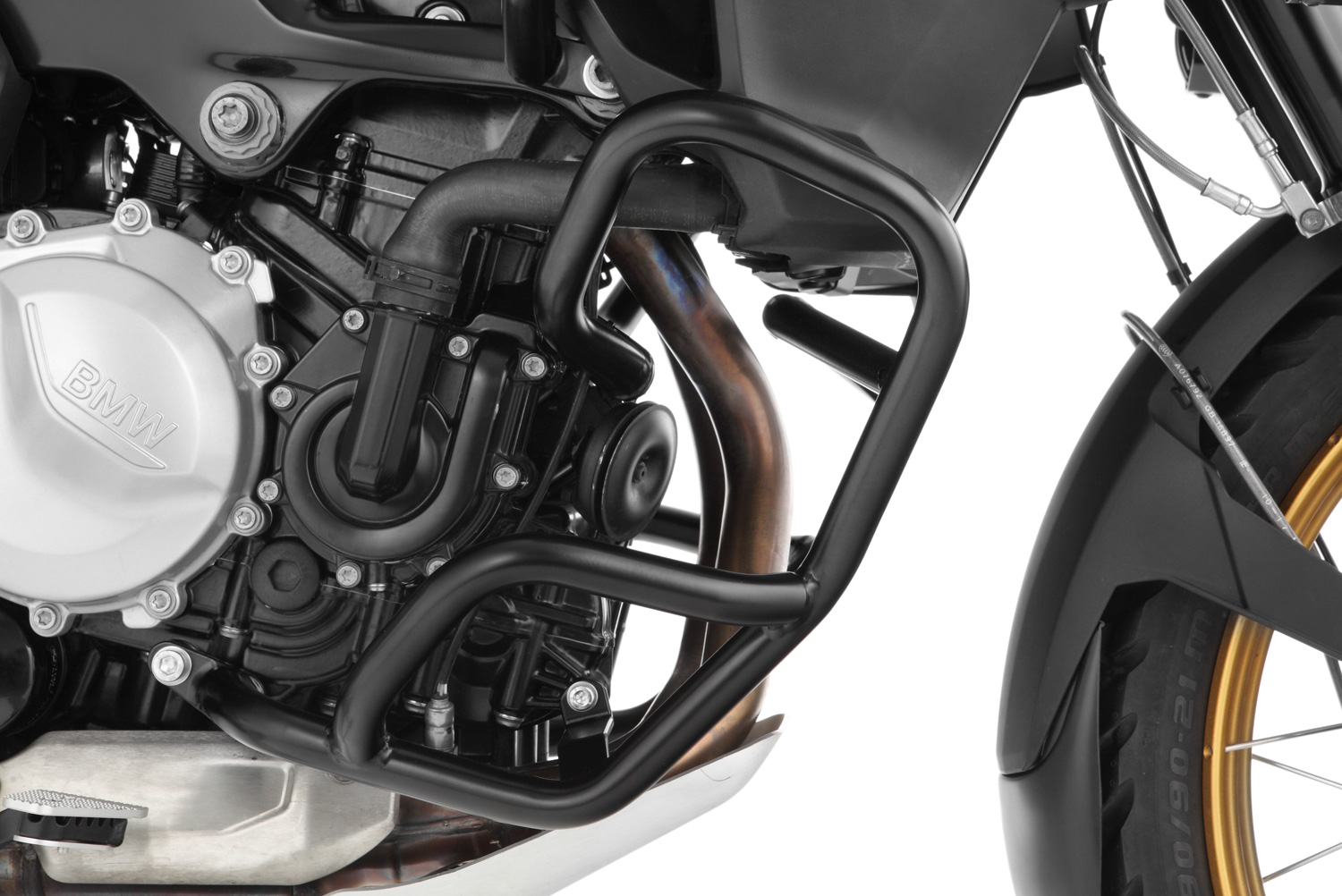

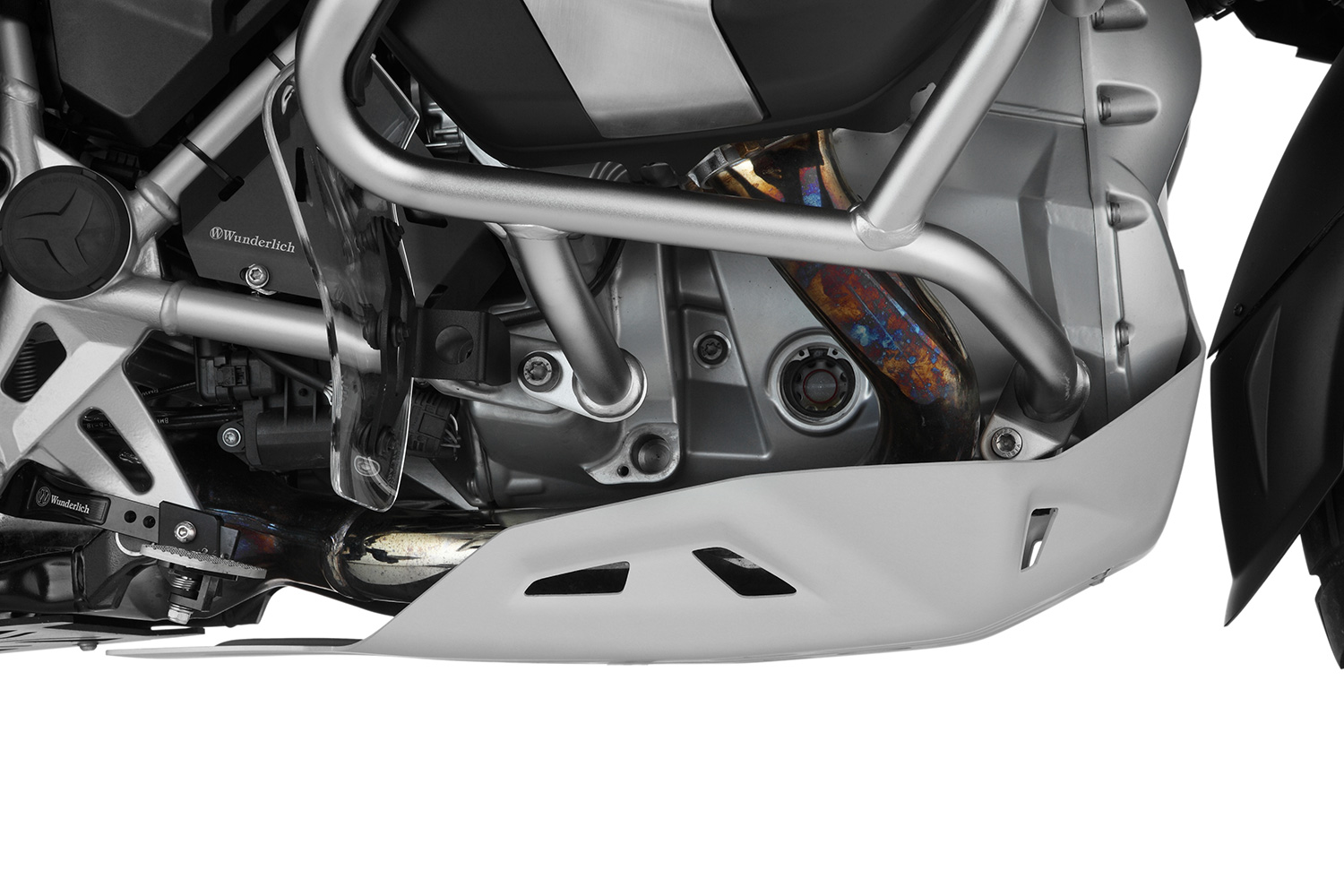

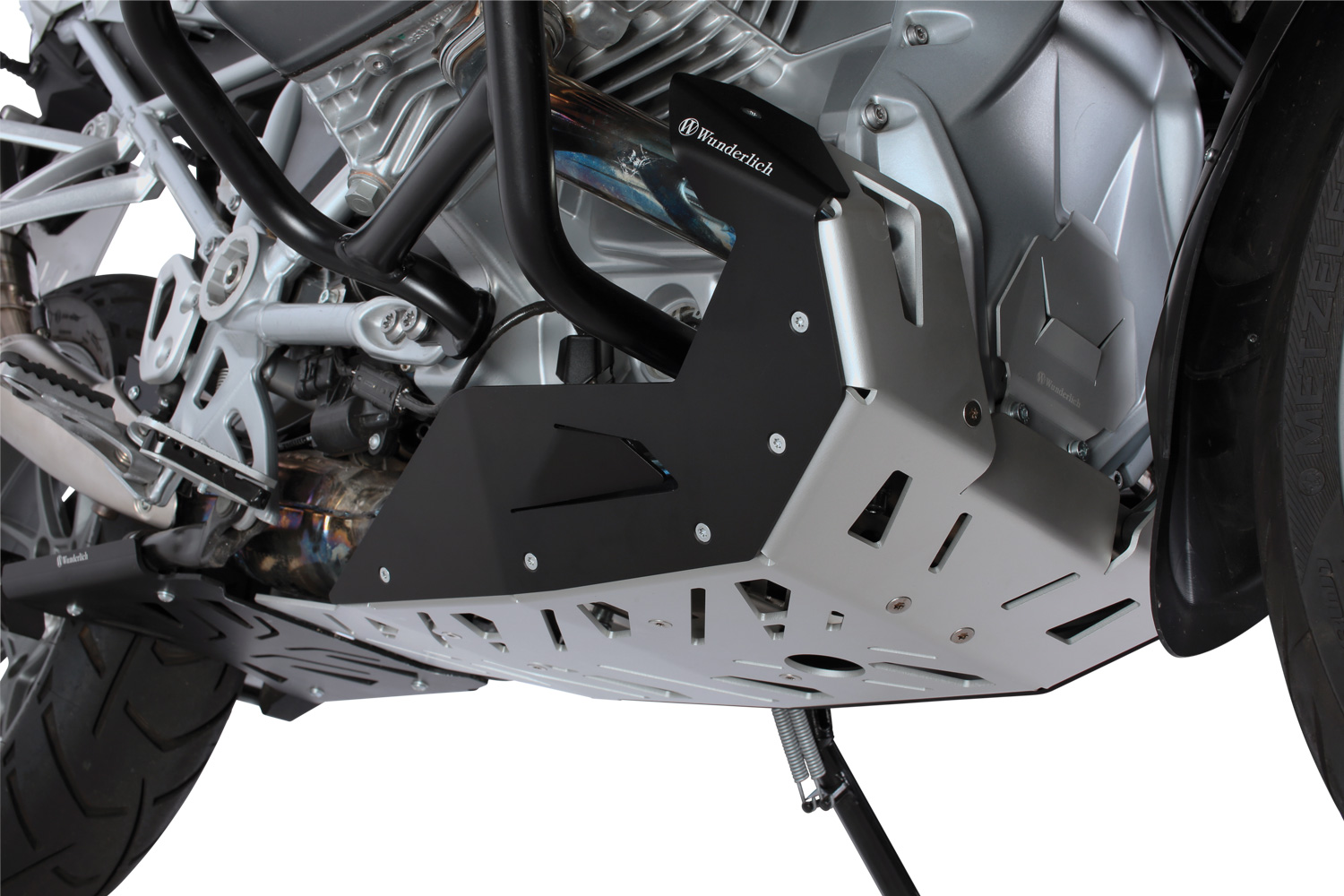

The engine protection for the R 1250 GS, the F 750/850 GS and F 850 GS Adventure.

Using the engine protection »EXTREME« as an example, we would like to show you a typical development process for a proprietary Wunderlich product.

- Maximum protection for engine and aggregates

- High rigidity and mechanical sturdiness versus

- Minimal weight

- Maximum protection with the best ground and lean angle clearance

- Secure attachment

- Product design or shape that only offers a small area of attack, that avoids levering or hooking of the bike over terrain

- Shock-absorbing attachment

- Anti-corrosion Openings so that the water can flow off freely after crossing rivers

- Good accessibility for maintenance

- Optimum constructive integration

- Functional design

- Integrated design

The focus is aimed especially at maximum protection and an optimum relationship between component rigidity and weight.

We apply our tried and tested evaluation matrix to the individual requirements. When it came to fulfilling the most important requirements, we were certain from the start that we wanted to further minimise the weight of the engine protection for the latest GS generation of the R and F models while simultaneously increasing component rigidity. At the same time, the engine protection should sit as snugly as possible. This reduced the frontal area of attack and achieves the maximum ground and angle clearance.

Special challenges

Design development and construction

Digitalisation

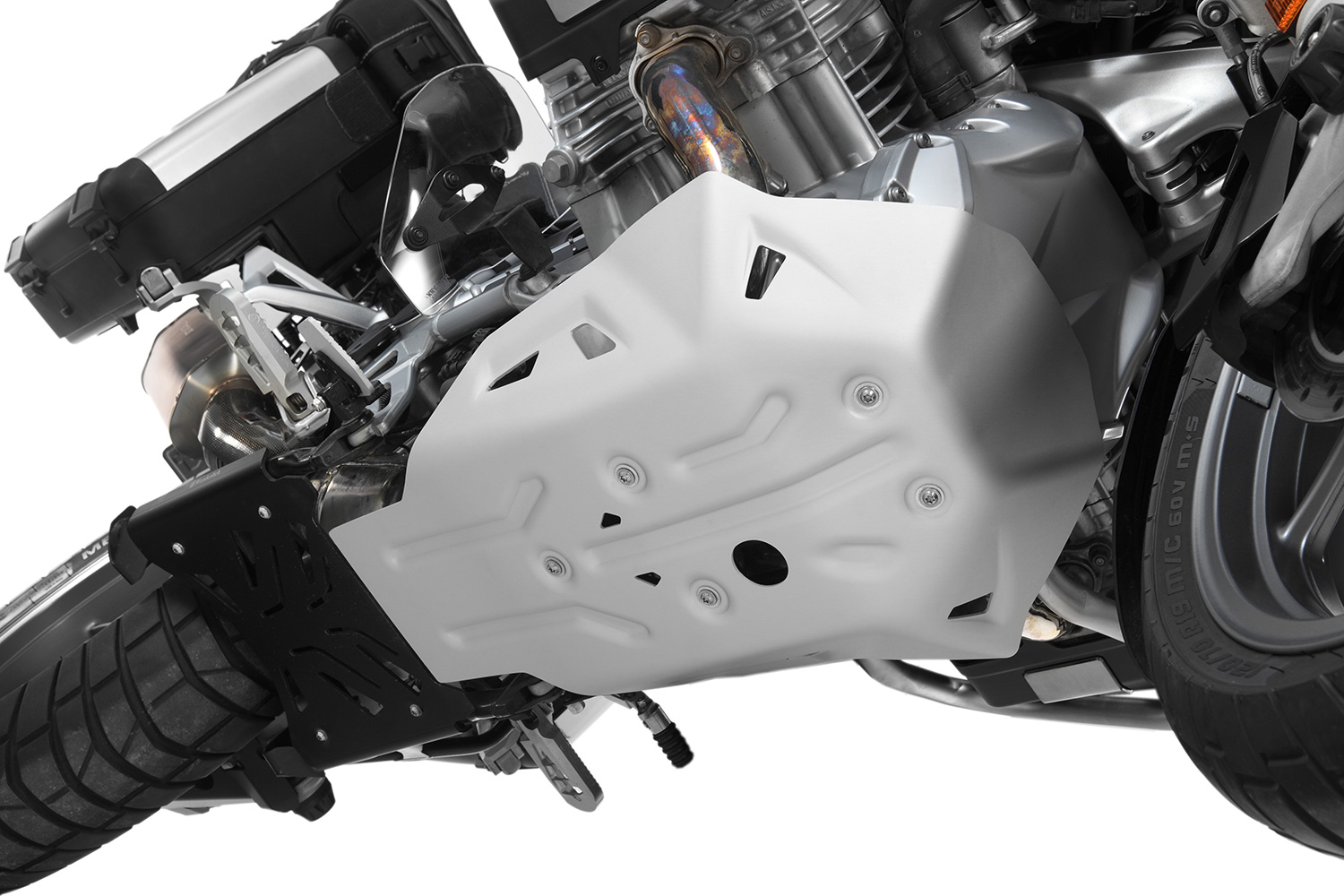

Treading new paths in manufacturing technology: the hydroforming process

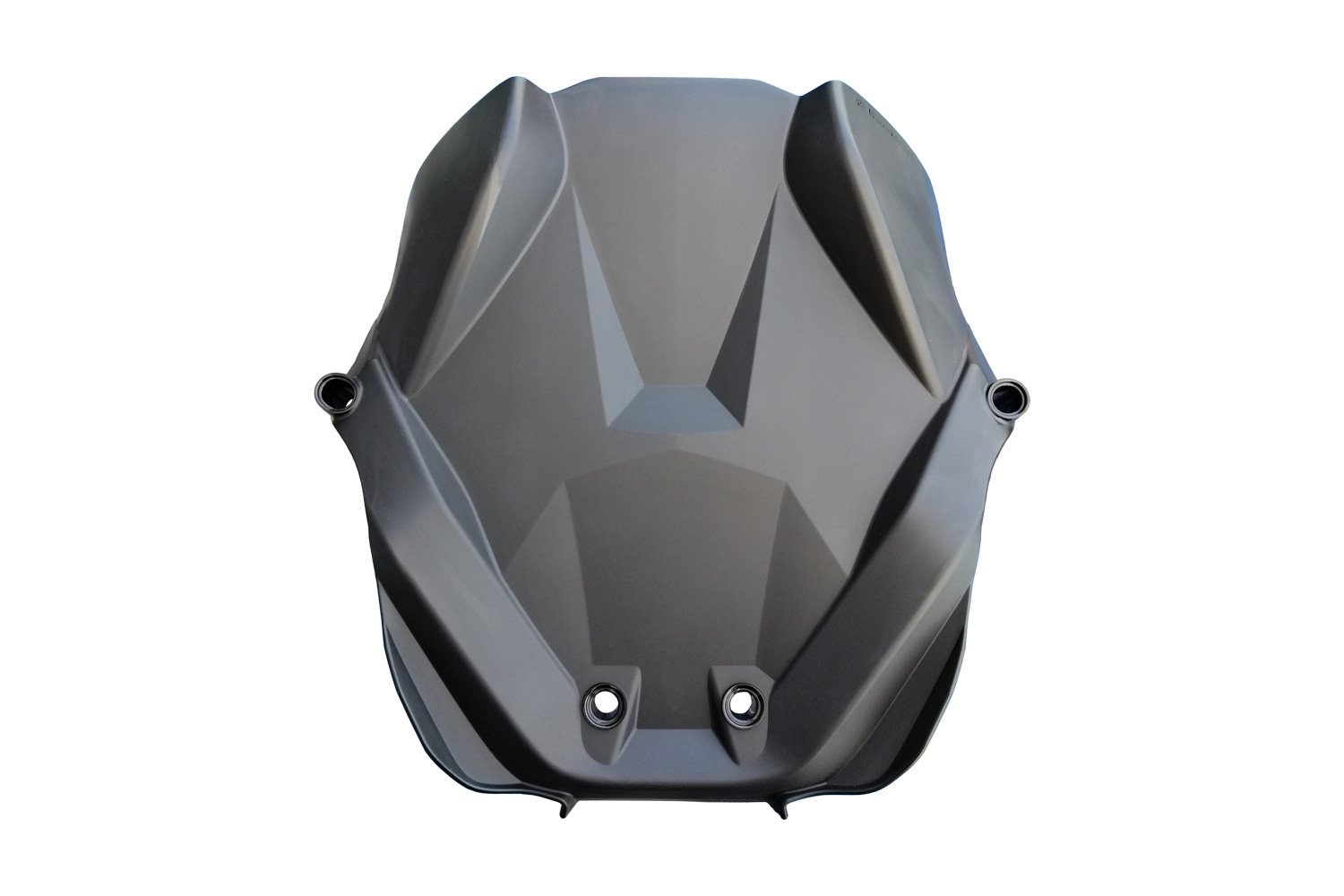

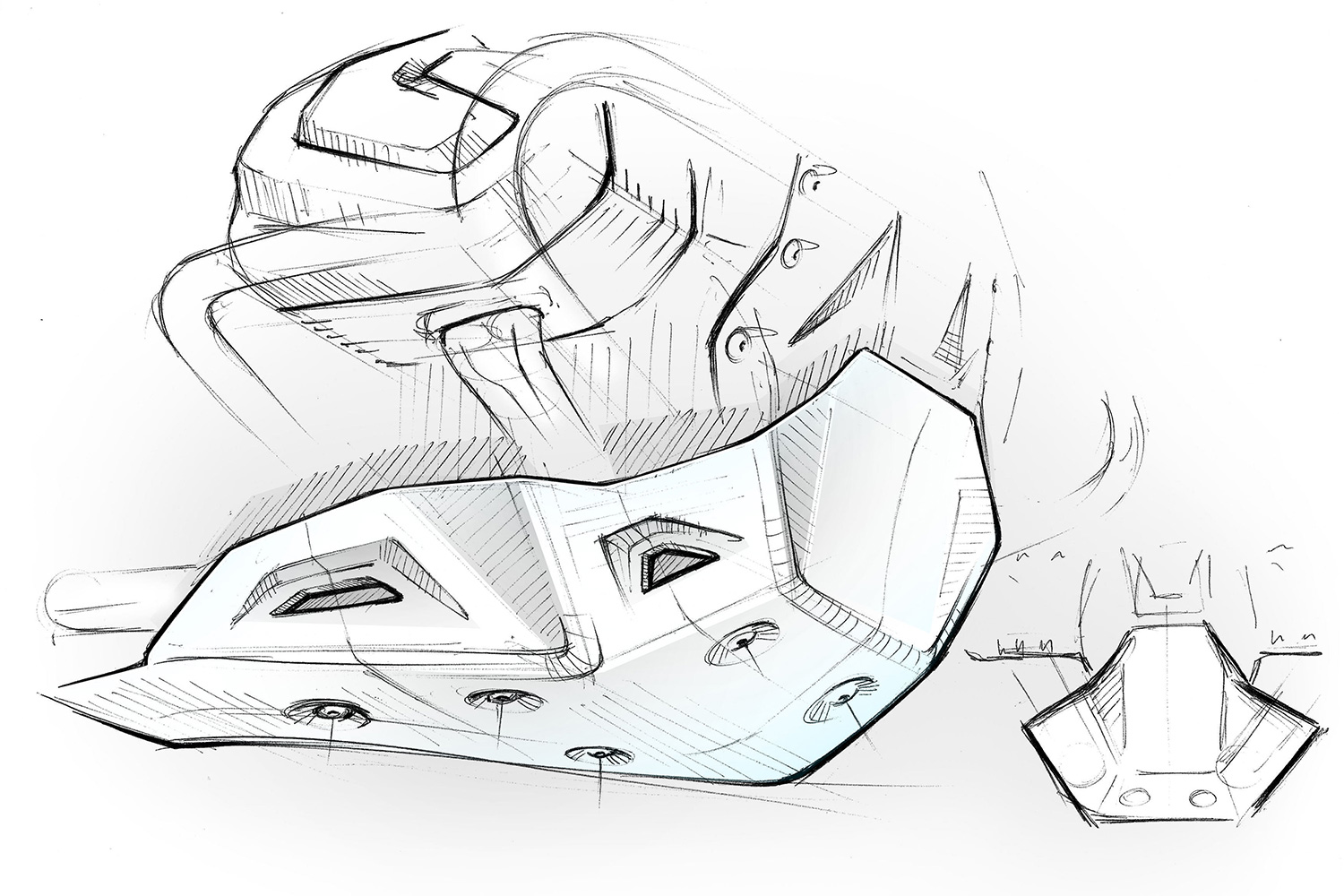

Draft with the first idea

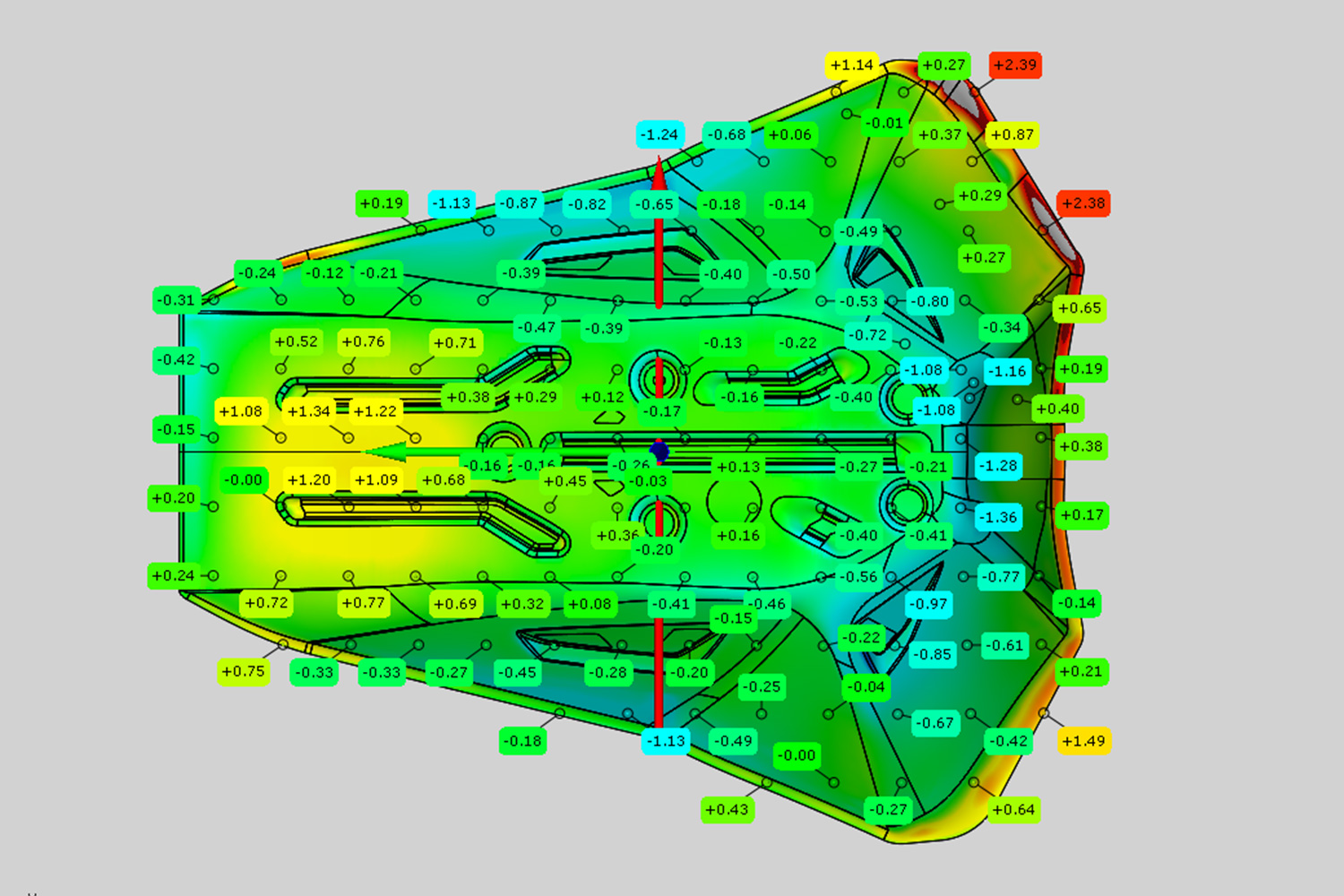

Representation of the stress distribution

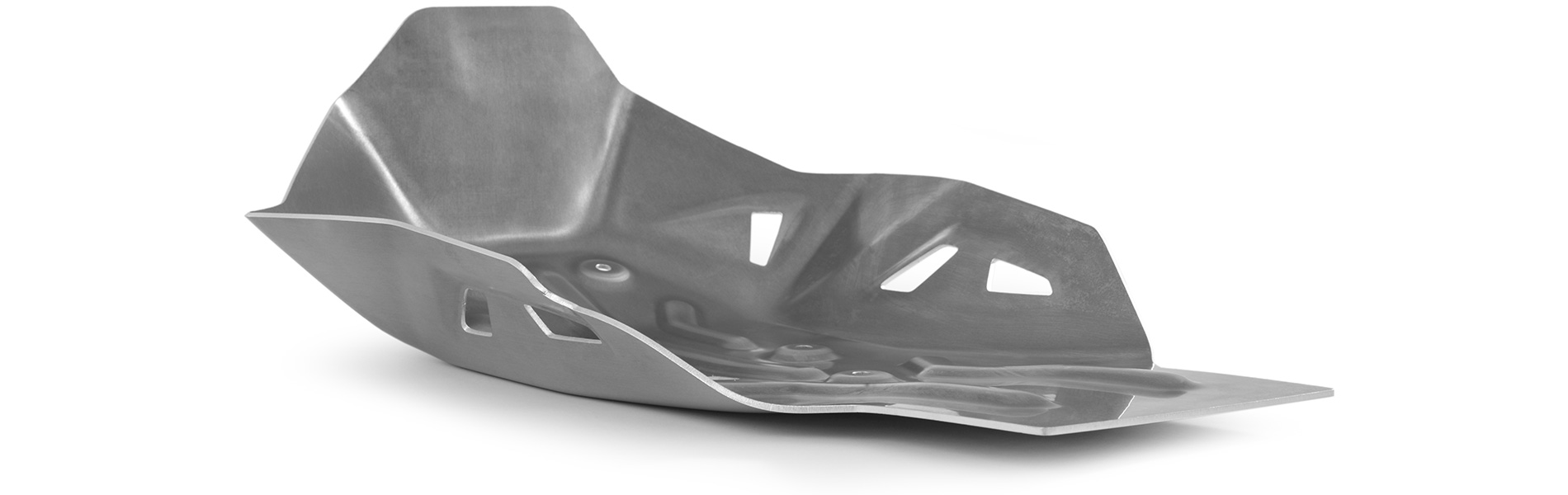

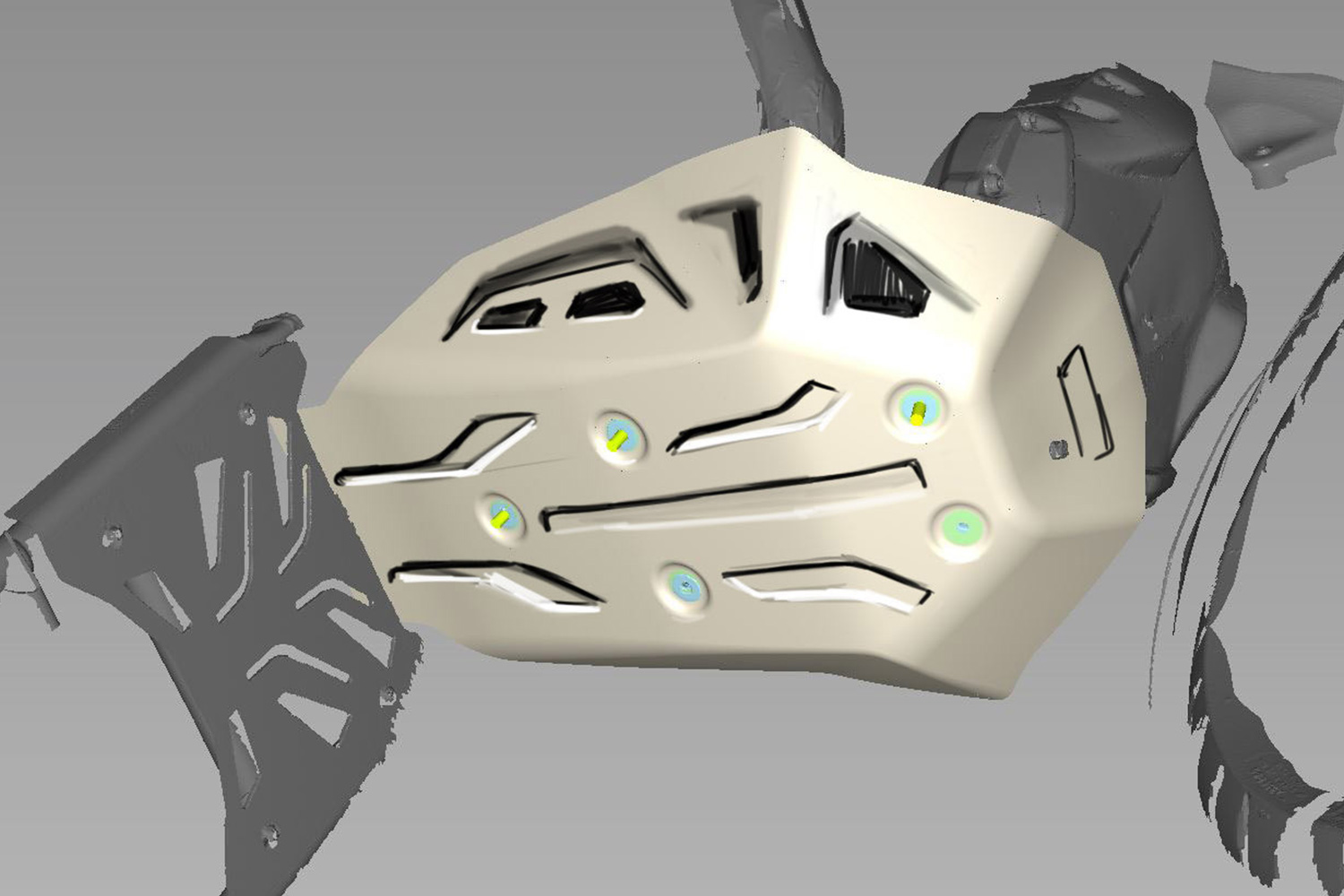

Rendered representation

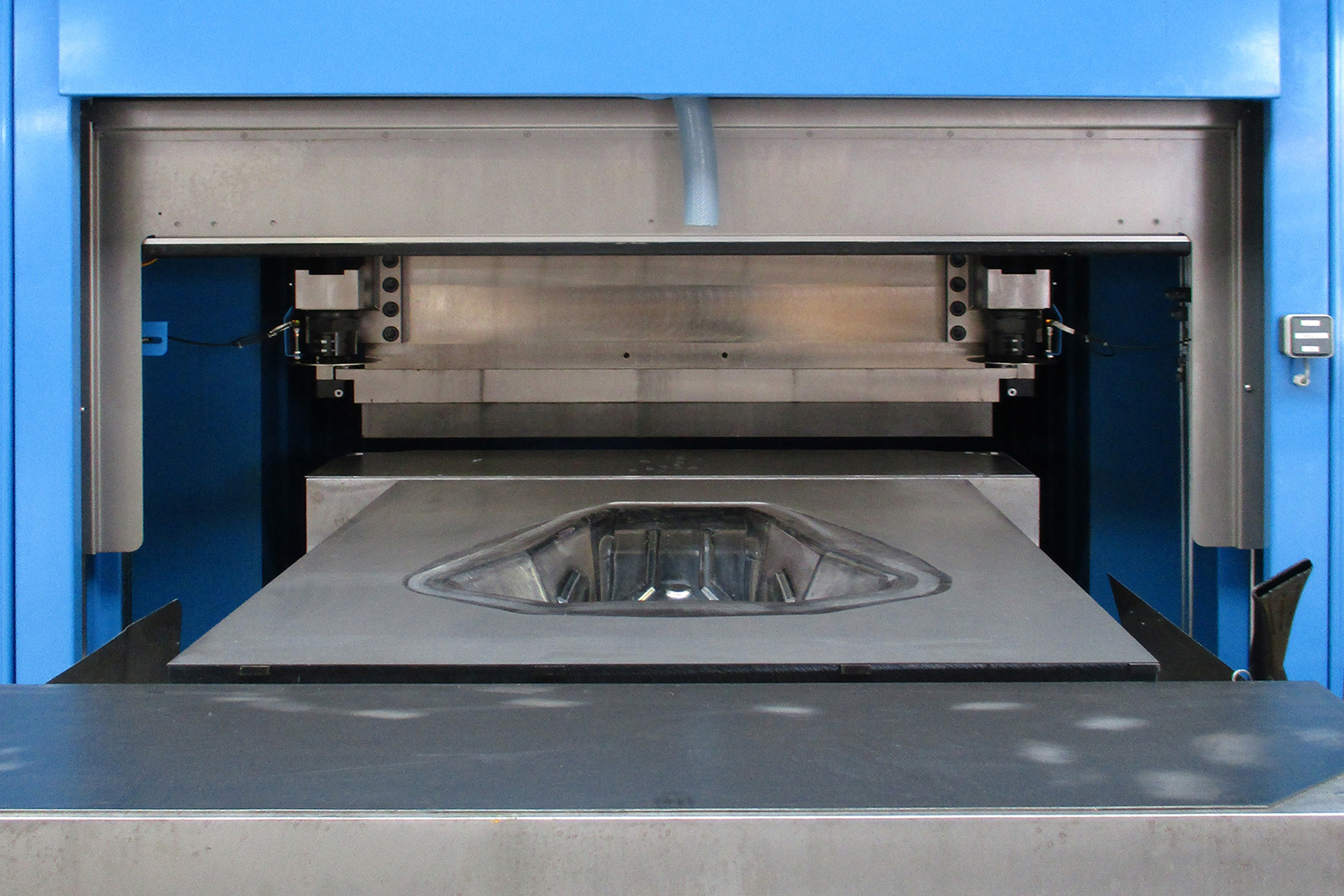

Hydroforming system with the die

The semi-finished product is...

...positioned with the die in the system.

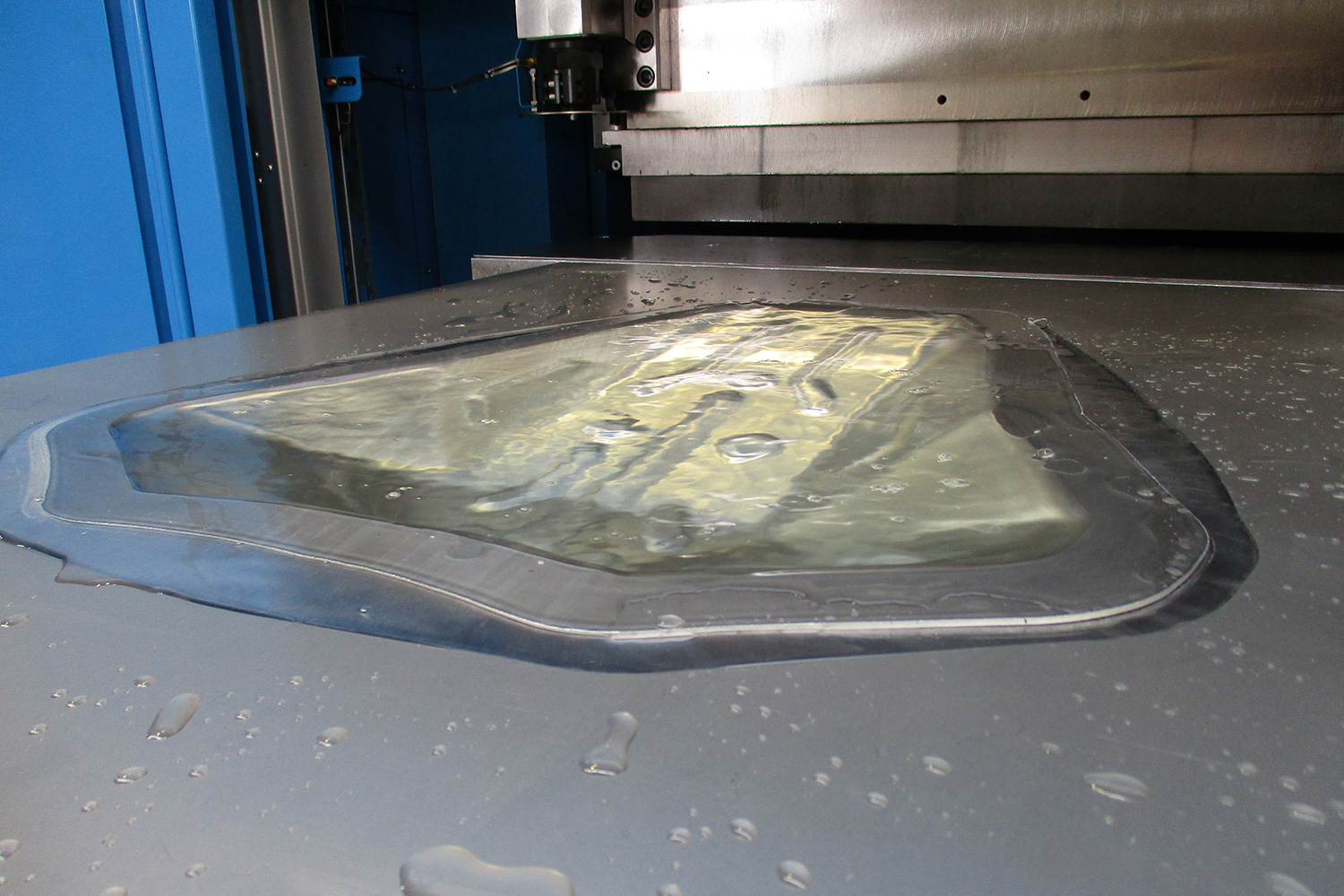

After the process, the hydro-...

The ready-made engine protection for the R 1250 GS series